This machine is suitable for the centralized cleaning and processing of various raw grains. Compared with traditional grain cleaners, it has significant advantages such as high output, multi-function integration, high precision, environmental protection, and energy saving. It is suitable for cleaning and processing various crop seeds or commercial grains such as corn, wheat, paddu rice, barley, peas, soybeans, mung beans, and oil seed.

Working Principle

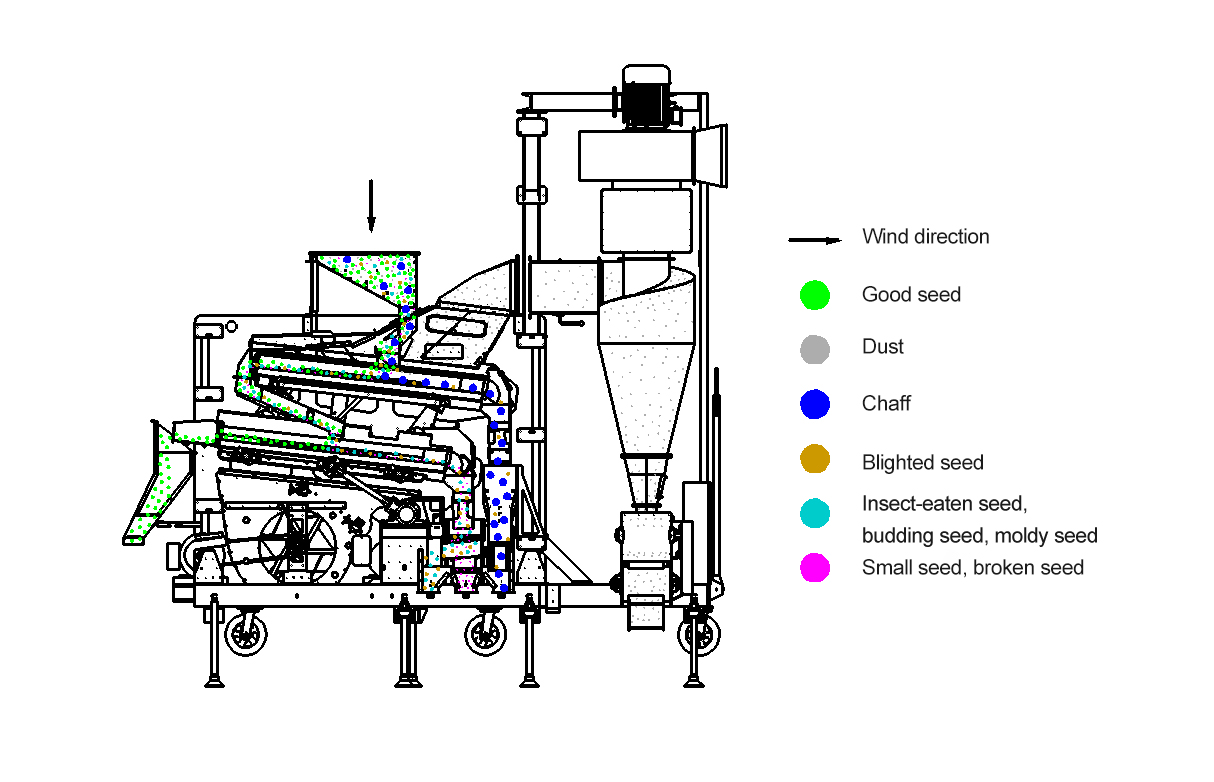

The material is conveyed through the conveying equipment and fed into the first negative pressure gravity table through the feed hopper. Air separation removes light impurities such as dust and chaff. These impurities pass through air clue and spiral dust collectors, and are then discharged and collected by the air lock. Gravity separation effectively removes lighter impurities such as straw and axle pieces. The material then passes through a grain guide mechanism and enters the second positive pressure gravity table. Gravity processing is performed by adjusting the air volume and baffle position to effectively remove impurities such as broken grains, blighted seeds, sprouted seeds, insect-damaged seeds, and moldy seeds. The finished product is discharged from the top of the gravity table.

Advantages

1. Advanced Technology

The side frame is formed from two 20mm thick steel plates through laser cutting and machining, resulting in a one-piece design that offers excellent strength and rigidity. Compared to traditional processes, it is more stable, reliable, and aesthetically pleasing.

2. Ultra-High Capacity

The ultra-wide gravity table allows for a primary sorting output exceeding 60t/h and a fine sorting output exceeding 30t/h.

3. High Cleanliness

The dust, chaff, and straw removal rate is ≥99%, while the removal rate for impurities such as husks and mold is ≥98%.

4. Dust Removal and Environmental Protection

The fully enclosed structure and four spiral dust collectors ensure a stable working environment.

5. Stability and Reliability

The unique self-balancing design effectively reduces abnormal vibration, reduces frame load, and improves stability. The eccentric drive utilizes spherical roller bearings, offering a higher load rating and longer life.

6. Flexibility and Convenience

The modular design of the dust removal and gravity units allows for flexible selection based on different scenarios and needs. Each trash discharge port on the machine features a symmetrical design, eliminating the need for forward or reverse rotation. Reverse installation allows for reverse trash discharge.

7. Multi-Purpose Machine

Suitable for cleaning and processing a wide range of crop seeds or commercial grains.

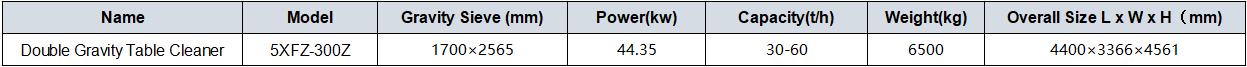

Specification

Processing demand survey

x